Special products and

Special Purposes of Use with Furwa veneer

cedar inlay soles, handbags, mousepads, mobile phone cases,

book covers, business cards, key cards, gift cards, postcards, ecologically sound wood labels, ski, snowboards and wakeboard.

Hand

Handbags

Furwa develops bag - compatible veneer surfaces.

Veneer edges are classical supplier products for the furniture industry. It is with these products that Furwa Furnierkanten GmbH, Walkertshofen, made a name for itself as a company specializing in surfacing and finishing.

At the same time the company also offers 3-D forming for its material, in this case especially for veneers used as glued elements in the automotive industry or used in injection molding.

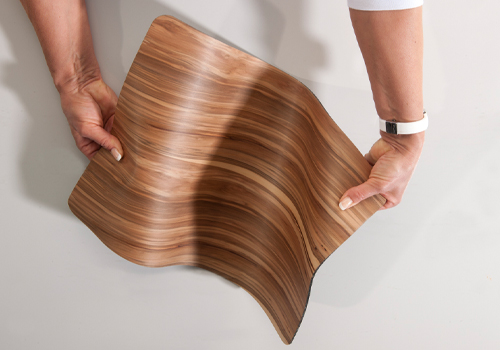

More unusual products like veneer table sets, mouse pads or mobile phone cases are now also part of the product range. And now the company is setting about capturing a place in the market with a spectacular new veneer application for supplying exclusive surface finishes for a trendy luxury segment - bags (specifically for woman) with large veneer applications.

What might sound somewhat bizarre at first is, on closer consideration, an interesting idea for positioning veneers in what is an exclusive segment which is receptive to natural surface finishes.

Gucci bags are known the world over. In this segment, leather as a natural material is absolutely dominant and is demanded by the market as a matter of course. Veneer would be the logical and incredibly attractive complement in visual terms, if its performance characteristics would permit such a use.

This applies both to the facing side, which needs to be sufficiently dirt- and water-repellent (whereby leather has its problems here too...), and the reverse side, requiring a base which allows great flexibility. Furwa has come up with a solution for both requirements.

read more here!

The surface finish is produced with a high-quality UV oil of the type used for tables made of solid wood. The rear side has function layer rolled onto it in the form of a 3 mm thick „Granuflex“ layer. This material, which is used among things for floors in sports facilities and for soundproofing, is highly flexible and provides the veneer with the stability required for its own 3-D movements.

The veneer suitable for the production of bags is comprised of a waterproof and thermally stable 4-layered composition. It has the effect of minimising characteristics typical of wood such as waviness and warping caused by moisture.

The veneer has a 0.1 mm fibrous web on the back; this is sanded down from a thickness of 0.6-0.5 mm to 0.4 mm for the surface finish and increased flexibility. The veneer prepared in this way is processed in combination with the bag leather in the standard production process. Of particular importance, of course, is an attractive and suitable bag design.

In this connection Managing Director Roland Reigbert was fortunate enough to make the acquaintance of famous bag designer Mety Darmali through a chance private contact.

This led to the first prototypes and trade fair models, which generated a good deal of positive feedback. In the meantime the company has taken one step further and pilot production with a predefined number of set draft designs has been set up and run with a production run of over 800. Managing Director Reigbert gets around a lot for PR purposes, with corresponding orders coming in up to July and delivery capability starting in October.

The veneers available for selection include Macassar, Vinterio or Fumed Oak, by way of example. The orders will be used as the basis for a stock collection. As for further marketing, possible solutions include both supplies to prominent bag manufacturers, special Mety Darmali collections or even marketing through industry suppliers/bag specialists.

With respect to pricing, this has been deliberately kept within the range considered realistic for designer products. The feedback so far has definitely shown that the veneer bag idea may well fill a real gap in the market; the models are also going down really well as promotional gifts. Veneer surfaces and the world of fashion simply go together; after all, they both have the same material aesthetics!

Accessories

Placemats & Mouse-Pads

FLEXIBLE AND NON-SLIP

FROM THE TREES OF THE WORLD ONTO ANY TABLE

15 WOOD SPECIES IN STOCK

OR ANY OF 100 WOOD SPECIES AS YOU DESIRE

The placemat/mousepad is made out of real wood with a waterproof and heat-resistant 4-layer structure. The protective surface is produced with a high-quality UV-Oil, as used in solid wood-table production.

The 4-layer construction with a granuflex rubber backing reduces the wood-typical characteristics such as buckling and waviness, caused by moisture. The rubber back ensures an even surface and high slip-resistance.

IMPORTANT

This is not a cutting board! Despite the water-resistant adhesion, the set is not suitable for the dishwasher, also the surface is not long-term moisture-resistant. To be cleaned just like any wood tables by damp, hot cloths with standard household detergent.

* general conditions:

Shipping costs per order 5,-€

prices incl. VAT.

Payment: Prepayment net after receipt of invoice

Delivery: within 1 week after payment received

If wood types and packaging quantities do not meet your expectations, please inquire specifically for larger quantities.

Please send a specific inquiry to:

We will get back to you shortly!

Telefon: +49 (0) 82 39 96 02 0

E-Mail: info@furwa.com info@furwa.com

Q&A

Why us?

Furwa is the oldest manufacturer of veneer edges in continuous rolls world-wide, and produces all customary edge types still today, such as real veneer edges, reconstituted veneer edges, thick veneer edges and profile wrapping veneers, at its plant in Walkertshofen.

From the base of the simple veneer edge, the technically demanding real veneer edge for door rebates in real wood has already been invented very early, which is produced highly-flexible lacquered and colour-set by Furwa in its standard production.

Today, FURWA is also an innovative specialist for veneer treatments of 3D formings, in particular for those veneers used for bondings and also used for the plastic rear injection moulding process in the automotive industry.

oldest Manufacturers

FSC certified

innovative Specialist for Veneer finishes

3D Deformations

Technically sophisticated

Made in Germany

%