Veneer D4 for 3D

the application possibilities in the field of 2D and 3D veneer deformations

D4 3D

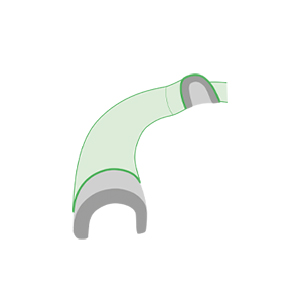

3D Veneers

Furwa veneer equipments for extreme adhesive requirements and extreme deformations

Furwa has developed a veneer backing based on a 50 g fleece, which fulfils the technical requirements of the automotive industry. It also fulfils the requirements for wrapping aluminium parts and plastic parts, especially if resistance to boiling water or long-term UV resistance are desired.

Fleece P50 Automotive strengthens veneer correspondingly strongly and has a considerably better tensile strength longitudinally too, and especially diagonally to the fibre. For this laminating process, PUR hot melts are not used because these systems are not long-term UV resistant (thin veneers are UV translucent!).

The flexibility of the veneer is determined by different sanding thicknesses (0.3-0.5 mm) or additionally even by flexing, depending on the desired deformation.

As a crowd puller at shows, such veneers were washed in a washing machine several times at 60 °C (140 °F) and ironed smoothly afterwards - no problem!

For the gluing process the most different methods can be applied; however, you should discuss these methods with us or have them tested in detail. Common adhesives: PVAc glues, urea resin wet, urea resin films, PUR dispersions, PUR hot melts, solvent adhesives, …

In the field of veneer such special treatments have even been further processed to 3D-moulded parts by means of the plastic rear injection moulding method for some time.

The purposes of use in the field of 2D and 3D veneer deformations can be simply explained by their finished products:

Car

- steering wheels

- dash boards

- ash tray lids

- gear sticks

Plastic Injection Moulded Parts:

- cases for cell phones

- light switch units . . .

Plastic and Aluminium Profiles

- window profiles

- front door profiles

- cover profiles, ...

Plywood preformed parts with small deformation radii

Textile processing and wickerwork products, ...

Whenever the requirements go beyond a normal veneer processing, you should talk to us.

Furwa has complete solutions for many veneer problems.

Please send a specific inquiry to:

We will get back to you shortly!

Telefon: +49 (0) 82 39 96 02 0

E-Mail: info@furwa.com info@furwa.com

Q&A

Why us?

Furwa is the oldest manufacturer of veneer edges in continuous rolls world-wide, and produces all customary edge types still today, such as real veneer edges, reconstituted veneer edges, thick veneer edges and profile wrapping veneers, at its plant in Walkertshofen.

From the base of the simple veneer edge, the technically demanding real veneer edge for door rebates in real wood has already been invented very early, which is produced highly-flexible lacquered and colour-set by Furwa in its standard production.

Today, FURWA is also an innovative specialist for veneer treatments of 3D formings, in particular for those veneers used for bondings and also used for the plastic rear injection moulding process in the automotive industry.

oldest Manufacturers

FSC certified

innovative Specialist for Veneer finishes

3D Deformations

Technically sophisticated

Made in Germany

%