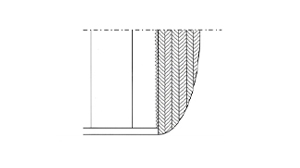

Thick Veneer Edging

1-3 mm

Thick

Thick Veneer Edging

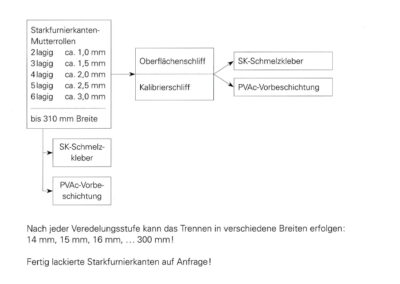

standard thicknesses:

approx. 1.0 mm 2-layers

approx. 1.5 mm 3-layers

approx. 2.0 mm 4-layers

approx. 2.5 mm 5-layers

approx. 3.0 mm 6-layers

- sanded surface

- sizing sanded on the back

- the rough backing supports adhesive strength

- priming hotmelt precoating

- bis zu 3,0 mm Stärke

- also prefinished lacquered

- special thicknesses are possible

Specially used fabric or fleece inlay for an extreme tensile strength,

e.g., for wickerwork of double-faced and open systems.

Continuous rolls ensure consistency in quality and in your production process.

Fixed lengths guarantee the highest standard!

The multilayer structure offers the same advantages against the solid wood edge as you know them from plywood boards, even though the veneer layers are glued longitudinally.

- highest strength in virtually each part of the edge

- best routing properties

- no buckling or cupping

- exact in size

Even with thick veneer the real performance features lie in the individual coordination of veneer quality and veneer technique as well as the processing technique!

The individual coordination and adaptation of thick veneer edges have a favourable effect especially in the BAZ edge processing.

Please send us a detailled inquiry in this case!

SPECIAL OFFERS

Standard Veneer Edging

No offers available at present.

Fineline-Edging

No offers available at present.

Thick Veneer Edging in rolls (1-3 mm)

No offers available at present.

Profile Wrapping Veneers in rolls

No offers available at present.

Edges for Door Rebates and Door Foldings

No offers available at present.

Special Veneer

No offers available at present.

Technical Treatments

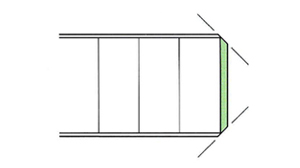

for chamfering

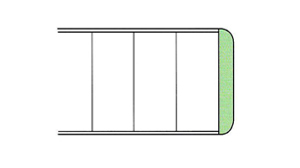

for routing a radius up to 3mm

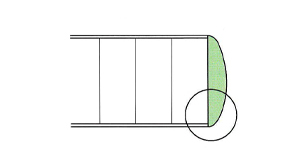

for bullnoising

Please send a specific inquiry to:

We will get back to you shortly!

Telefon: +49 (0) 82 39 96 02 0

E-Mail: info@furwa.com info@furwa.com

Q&A

Why us?

Furwa is the oldest manufacturer of veneer edges in continuous rolls world-wide, and produces all customary edge types still today, such as real veneer edges, reconstituted veneer edges, thick veneer edges and profile wrapping veneers, at its plant in Walkertshofen.

From the base of the simple veneer edge, the technically demanding real veneer edge for door rebates in real wood has already been invented very early, which is produced highly-flexible lacquered and colour-set by Furwa in its standard production.

Today, FURWA is also an innovative specialist for veneer treatments of 3D formings, in particular for those veneers used for bondings and also used for the plastic rear injection moulding process in the automotive industry.

oldest Manufacturers

FSC certified

innovative Specialist for Veneer finishes

3D Deformations

Technically sophisticated

Made in Germany

%